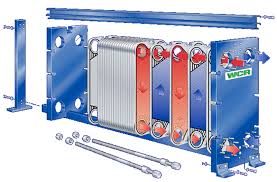

What Is A Plate Heat Exchanger?

Plate heat exchangers (or PHEs) were invented in 1923 by Dr Richard Seligman and changed the way that fluids were indirectly heated and cooled. A plate heat exchanger utilises metal plates in order to transfer heat between two fluids making it a better choice than a conventional heat exchanger since the fluids have exposure to a greater surface area as they spread across the plates. As this facilitates heat transfer, the speed of warming increases. It is for this reason that plate heat exchangers are now becoming more common, with small brazed versions being used inside combination boilers and many larger buildings relying on them entirely for the supply of their hot water, using gaskets between the two plates.

Plate heat exchangers (or PHEs) were invented in 1923 by Dr Richard Seligman and changed the way that fluids were indirectly heated and cooled. A plate heat exchanger utilises metal plates in order to transfer heat between two fluids making it a better choice than a conventional heat exchanger since the fluids have exposure to a greater surface area as they spread across the plates. As this facilitates heat transfer, the speed of warming increases. It is for this reason that plate heat exchangers are now becoming more common, with small brazed versions being used inside combination boilers and many larger buildings relying on them entirely for the supply of their hot water, using gaskets between the two plates. How Do Plate Exchangers Work

Plate exchangers transfer heat from one fluid to another via a sectional division. They are made from plates that have hollow spaces between them. This space forms ducts through which the fluids can flow, thus exchanging heat via the plates. There may be a varying number of plates inside a heat exchanger depending on its kW (heat exchange capacity). The more plates used in the PHE, the bigger its capacity.

What Are The Advantages Of A Plate Heat Exchanger?

very little room. They can be used either in their own right or as part of another heating system such as a combination boiler. The benefits of Plate Heat Exchangers include the fact that they come in several different sizes to accommodate different applications and the amount of heat transfer for their size is extremely efficient with PHEs offering unlimited supply options.

very little room. They can be used either in their own right or as part of another heating system such as a combination boiler. The benefits of Plate Heat Exchangers include the fact that they come in several different sizes to accommodate different applications and the amount of heat transfer for their size is extremely efficient with PHEs offering unlimited supply options. Disadvantages Of Plate Heat Exchangers

While plate heat exchangers offer many advantages for both commercial and domestic customers, there are some disadvantages. One of their main downsides is that they require regular maintenance, and the larger the exchanger, the more maintenance it will require.

Because of the high flow rate and rapid interchange involved with plate heat exchangers, debris builds up quickly in the system and the larger amounts of scale deposits begin to form over time. This means that regular cleaning must be carried out in order to ensure that the heating system continues to function effectively and to its optimal level.